Anaerobic Digestion (AD)

Anaerobic Digestion (AD)

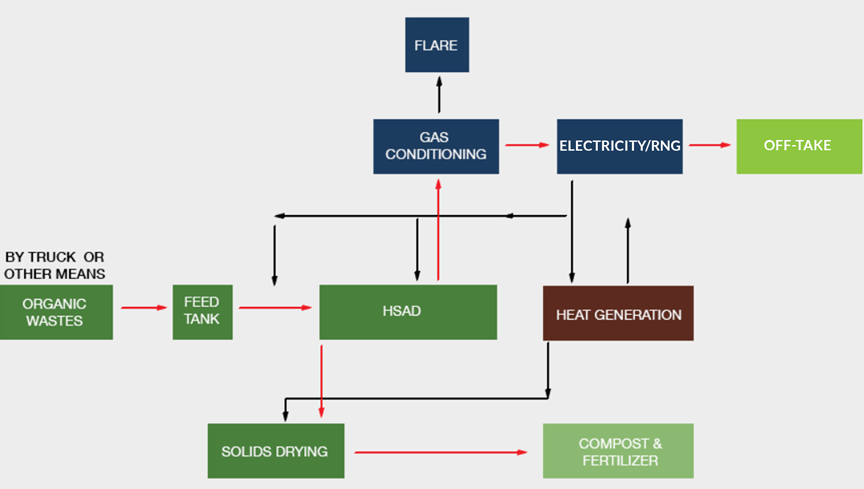

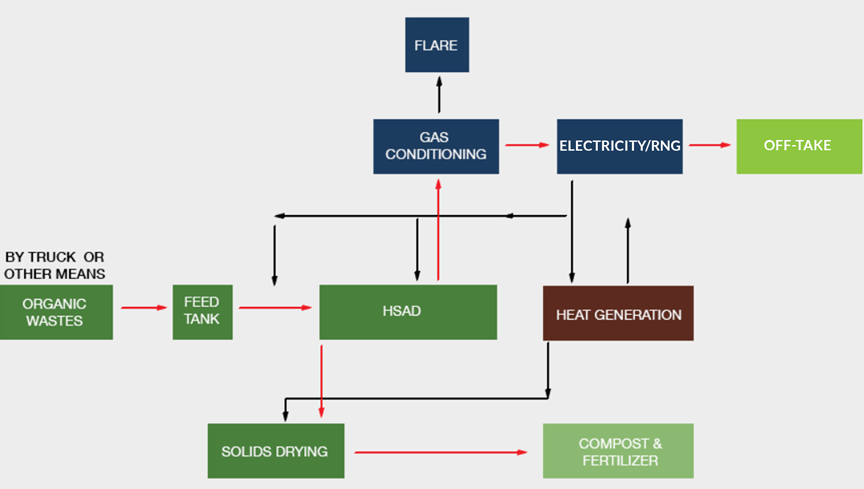

- Anaerobic digestion is the natural process in which microorganisms break down organic matter in the absence of air (an anaerobic environment). Anaerobic digestion creates usable products such as biogas and digested material.

- Anaerobic digesters are tanks in which the management of organic wastes occurs to produce gas and digested materials. These tanks minimize odors, reduce pathogens, and reduce solid wastes. Anaerobic digesters are also referred to as “anaerobic digestion systems”, “biodigesters” or simply “digesters”.

- The benefits of anaerobic digestion include:

- Nutrient management alternatives

- Production of renewable energy

- Soil improvement opportunities

- Diversion of organic wastes from less preferred disposal options

- Methane emissions reduction

- Biogas is made up of methane and carbon dioxide, which are powerful greenhouse gases. Anaerobic digesters are designed to capture these gases so they do not escape to the atmosphere. In most cases, the feedstocks used in digesters would have released methane directly as they decompose in lagoons or landfills. In addition, using biogas for heat or electricity means that less energy needs to be produced by power plants. This reduces the amount of carbon dioxide emitted to the atmosphere by burning fossil fuels.

- Biogas can replace fossil fuels for the production of heat, power and fuel. With additional processing, biogas becomes renewable natural gas that can be used in the same place as fossil fuels.